Mining Technologies

About mining technologies

Mining Technologies

Densep Technologies has significant experience with most material handling and mining machines, plants, facilities and structures including

- Conveyors

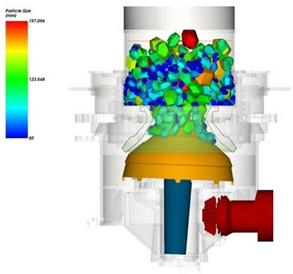

- Grinding Machines

- Scrubbers, Stackers/Reclaimers

- chutes, hoppers, bins,

- vibrating screens,

- feeders

- dozer traps,

- car dumpers, sampling stations

- ore out-loading facilities

- Froth floatation circuits

- Thickeners and classifiers

The QA system utilised by Densep Technologies includes specific procedures for design, design review, project management, site troubleshooting, post-processing, analysis and reporting.

OUR PROJECTS

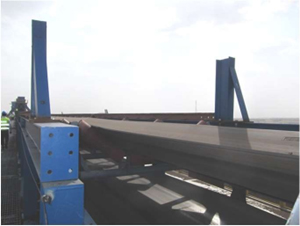

Stacker Reclaimer Thar Coal Handling Plant

Upon SECMC (Sindh Engro Coal Mining Company) request, Densep Technologies had undertaken a detailed engineering review of the stacker reclaimer design and its specification to ensure machine compliance to international standards and had advised SECMC about avoiding a number of costly non critical machine features.

OUR PROJECTS

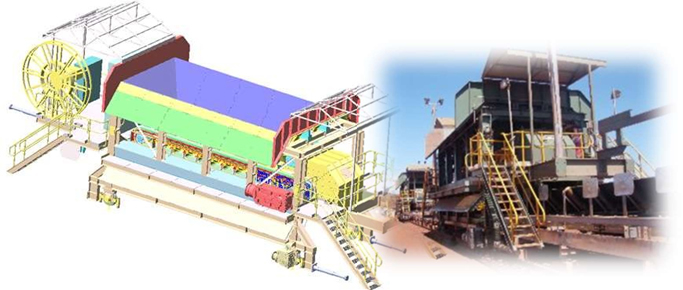

Bulking-in Hopper System

A 30 m^3 dual side FEL fed hopper system was designed as a redundancy in an out loading circuit to ensure throughput continuation during reclaimer breakdowns. The machine was mobile and rail mounted over the stockpile reclaiming conveyor.

OUR PROJECTS

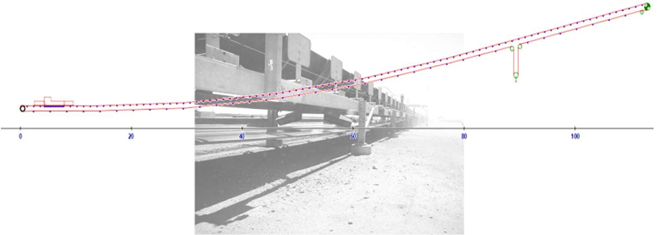

Conveyor Engineering and Design Review – Thar Coal Handling Plant

A complete engineering review of Thar Block II project conveyors 2021B, 2023A and 2024 was undertaken on SECMC request. The review involved full modeling of the entire conveyor systems from minimum available information. The review report had shown some serious shortcomings and inconsistencies. The review later helped in addressing the conveyor engineering issues in an structured manner.

OUR PROJECTS

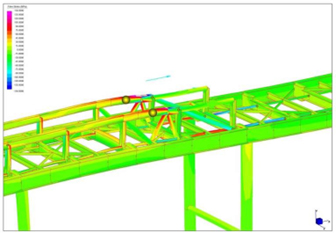

Buffer Stop Frame FEA – Thar Coal Handling Plant

A complete engineering review of Thar Block II project conveyors 2021B, 2023A and 2024 was undertaken on SECMC request. The review involved full modeling of the entire conveyor systems from minimum available information. The review report had shown some serious shortcomings and inconsistencies. The review later helped in addressing the conveyor engineering issues in an structured manner.

The analysis had resulted in an efficient redesign of the stop frame while ensuring even load distribution to supporting truss and trestles.